Generating high-quality PLC code | MHS

We helped MHS to improve their software quality and bring it to the next level.

Material Handling Systems (MHS) is a global system integrator, specialized in the design, construction and installation of intralogistic solutions. MHS is committed to increase the competitive advantage of its customers around the world. It is therefore key to develop its solution in an efficient and reliable manner. The company is investing in process optimization around the design of their sorting solutions. Now MHS aims to innovate even further, and SIG helps them to achieve their goals.

The challenge

MHS designs the models of their installations in a program called Demo3D. Everything is carefully thought-out based on their clients’ wishes: from the speed of the belt conveyor to the placement of the sensors and the most efficient construction. With a single click, designers generate a bill of material needed for the installation. Whereas this is a fully automated and efficient process, the development of the software was a manual process. Developing software that automatically generates PLC code improves reliability and quality.

“We want to scale our services around the globe, so we needed to improve our software,” says the R&D Project Manager at MHS Houten. “Developing and testing the software that runs in the PLC is taking too much time. Decreasing our lead-time for our installations makes it possible to deliver more quickly to our clients and meet the fast changing requirements.”

The impact of the SIG solution

The engagement with SIG wasn’t about raising quality awareness, since the engineers at MHS are already aware of this important aspect. SIG helped MHS to improve their software quality and bring it to the next level. Steering on quality saved MHS at least 2,000 hours of work. Creating high-quality code is a process. This is embedded in the development culture at MHS. The result is not just improved software quality, but also a delivery chain which is prepared for efficient delivery of material handling systems.

In short, the engagement with SIG has delivered:

- Improved software quality

- Increased scalability

- Reduction and faster resolution of errors

- Shorter delivery time

“With the help of SIG we brought the software quality to the next level which helps us to deliver our installations faster.”

R&D Project Manager at MHS Houten

How did SIG help MHS?

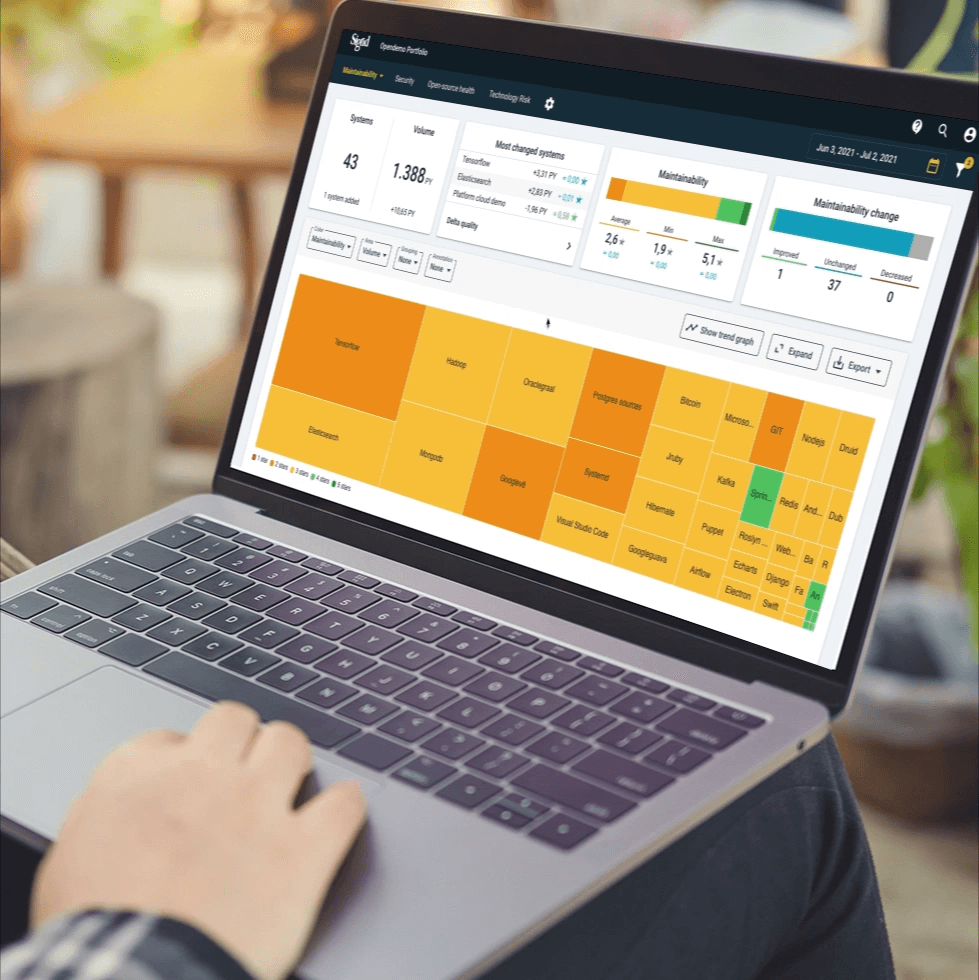

To achieve the desired scalability, MHS started the PLC Standardization project: a system to generate PLC code automatically based on the design in Demo3D. SIG helped to ensure a high quality level of this generator and the PLC-code library. This ensures that potential risks are encountered early on in the process, so they can be mitigated and solved before causing problems. Using the online monitor, engineers have significantly increased the quality of the software, which shortens error resolution and delivery times of the software.

The board members recognized the importance and gave people the opportunity to free up time to work on the software quality. No doubt, this contributed to the increase of software quality at MHS.

“It is a huge benefit that the installation, including the software, can be managed mainly within one environment. If for instance the configuration of the belt conveyor needs to be adjusted, then you can easily regenerate the code.”

R&D Project Manager at MHS Houten